The mining industry, a cornerstone of global economic development, is experiencing a technological revolution driven by unmanned aerial vehicles (UAVs) — drones. These sophisticated flying machines are proving to be invaluable tools in mineral exploration, with the ability to pinpoint valuable metals and streamline the mining process.

The Power of Drones in Mining Exploration

Drones have many uses in mining, from surveying and mapping to tailing dams monitoring, and mining companies have been quick to adopt the technology. A recent survey found that 65% of mining operations had invested in drone technology in 2022, up from 44% in 2018.

Traditional mineral exploration methods often involve time-consuming and resource-intensive processes. Mining exploration operations carried out in the traditional way present one of the highest risks to personnel. With the technological evolution and the use of drones in mining, mining exploration methods have been adapted so that today they include the use of drones and photogrammetric methods based on which high-resolution orthophoto plans, 3D models, multispectral analysis, etc., are obtained and used.

Drone surveys for mine sites enable more rapid data collection, nearly 30x faster than traditional land-based practices carried out by personnel.

The Magnetometer Payload

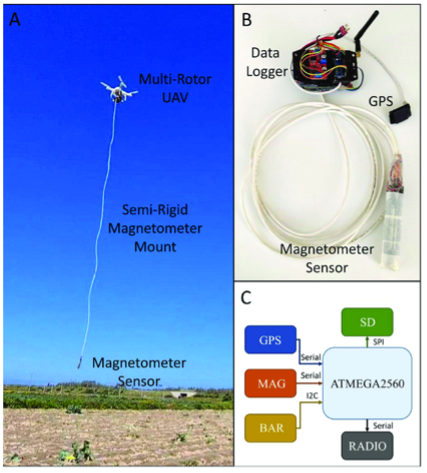

At the heart of this technological advancement lies the magnetometer — a device capable of measuring variations in the Earth's magnetic field. In the context of mining, magnetometers play a crucial role in detecting and mapping subsurface metallic structures. Mounted on a drone, this payload becomes a powerful tool for geophysical surveys and mineral exploration.

By measuring the magnetic anomalies, or deviations from the expected value, magnetometers help identify the location, depth, and shape of mineral deposits. Magnetometers are mounted on drones and flown over large or inaccessible areas, creating a magnetic map that can be analyzed and interpreted by geologists.

The unmanned aerial vehicle (UAV)-magnetometer system. (A) The UAV equipped with the data logger carrying the magnetometer sensor; (B) the magnetometer system, data logger, and sensors; (C) diagram of the data acquisition and control system.

How Drone-Mounted Magnetometers Work

- Data Collection: The drone, equipped with a magnetometer, flies over the target area, collecting magnetic field data with precision.

- Magnetic Anomalies: Metals beneath the Earth's surface create disturbances in the magnetic field. The magnetometer detects these anomalies, indicating the potential presence of valuable minerals.

- Data Analysis: The collected data is then processed and analyzed, revealing detailed information about the type, size, and depth of the metallic deposits.

Benefits of Drone-Mounted Magnetometers in Mining

When comparing UAV surveys with traditional methods, it's essential to consider two key aspects: UAV vs Ground Surveys and UAV vs Airborne Surveys.

In the case of UAV vs Ground Surveys, data from GEM Systems reveals a remarkable efficiency difference. While a ground operator might require 10 days to survey a 100-kilometer line, drones can accomplish the same task within a single day- greatly reducing costs and increasing operator’s safety.

On the other hand, UAV surveys address challenges encountered with Airborne (manned aircraft) surveys. Due to safety restrictions, aircraft fly at a minimum height of 300 feet, while UAV magnetometer surveys are flown at 100 feet, resulting in a much stronger and higher quality signal. Additionally, the ease of launching, mobilizing, setting up, and re-energizing drone magnetometers, combined with their capability to operate in various weather conditions and at night, further distinguishes them from their airborne counterparts.

- Cost-Effectiveness: Traditional exploration methods, such as ground-based surveys or airborne magnetic surveys, can be expensive. Drones significantly reduce costs by offering a more efficient and targeted approach to data collection.

- Rapid Surveying: Drones cover large areas quickly, allowing mining companies to survey expansive territories in a fraction of the time it would take with conventional methods.

- Reduced Environmental Impact: Drones minimize the environmental footprint associated with traditional exploration methods. Their non-intrusive nature reduces disturbance to ecosystems and local communities.

- High Precision: The combination of drone mobility and magnetometer sensitivity provides high-resolution data, enabling precise identification of metallic deposits.

- Improved Safety: Sending drones into potentially hazardous or inaccessible areas reduces the need for on-ground surveys, enhancing safety for exploration teams.

Real-World Applications

Mining companies worldwide are increasingly adopting drone technology with magnetometer payloads for exploration and prospecting. Whether it's searching for gold, silver, copper, or other metals, the use of drones streamlines operations, mitigates risks, and maximizes the potential for discovering economically viable deposits.

In 2021, Canada’s second largest Nickle deposit was discovered using UAV technology.

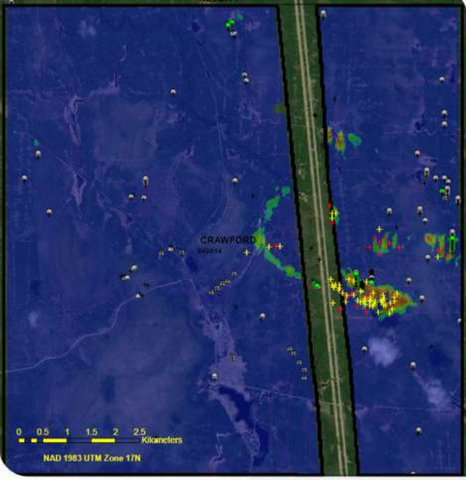

Image prior to scanning:

Image after UAV scanning:

Future Perspectives

As drone technology continues to evolve, the capabilities of magnetometer-equipped UAVs are expected to advance further. Integrating artificial intelligence for real-time data analysis, improving payload efficiency, and expanding the range of detectable metals are just a few possibilities on the horizon.

The marriage of drone technology and magnetometers is transforming the landscape of mineral exploration within the mining sector. With increased efficiency, reduced costs, and minimized environmental impact, the use of drones equipped with magnetometers is propelling the industry into a new era of precision and sustainability. As we look to the future, these technological innovations promise not only to uncover hidden riches beneath the Earth's surface but also to redefine how we approach resource exploration and extraction.